Started In

One of the leading textile manufacturer in Egypt

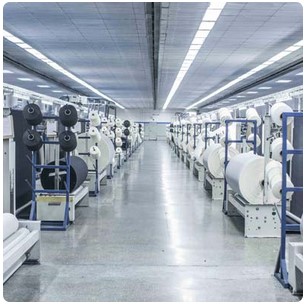

ULHWATEX Misreya Korea for Textile Industry is a leading Egyptian joint-stock company, established in 2002 under Investment Law No. 8 of 1997.

With over 25 years of experience, we specialize in manufacturing high – quality woven fabrics using advanced machinery and skilled professionals.

Our process covers twisting, sizing, dyeing, and finishing, ensuring durable and precise textile solutions. ULHWATEX proudly exports to several international markets, offering reliable and consistent fabric supply for diverse applications.

Manufacturing Process Overview:

Manufacturing Process

Our manufacturing journey is a blend of precision, technology, and craftsmanship — delivering high-performance fabrics through each of the following essential steps:

1- Twisting & Weaving

Twisting strengthens staple yarns and readies them for weaving; combined with high-twist techniques and contrasting materials, it creates fabrics with texture, elasticity, and depth.

2- Sizing Process

Sizing involves applying a protective adhesive coating to the yarn’s surface. This process minimizes friction during weaving, reduces yarn breakage, and improves the weaving efficiency and fabric quality.

3- Dyeing

It involves the interaction between dye molecules and fiber structures, allowing the dye to penetrate the inner layers of the fabric for deep, uniform, and long-lasting color results.

4- Finishing Processes

Finishing unites function and appearance; treatments improve fabric look, feel, and durability through processes like softening, shrink control, anti-pilling, and wrinkle resistance.

5- Quality Control

“Before leaving our facility, fabrics undergo strict quality checks for strength, colorfastness, texture, and specifications — ensuring top industry standards and customer satisfaction.”

Manufacturing Process

Our manufacturing journey is a blend of precision, technology, and craftsmanship — delivering high-performance fabrics through each of the following essential steps:

1- Twisting & Weaving

Twisting is a crucial step in the production of staple yarns. It enhances yarn strength and prepares it for weaving.

When combined with contrasting materials and high-twist techniques, the weaving process produces fabrics with dynamic textures, increased elasticity, and visual depth.

2- Sizing Process

Sizing involves applying a protective adhesive coating to the yarn’s surface.

This process minimizes friction during weaving, reduces yarn breakage, and improves the weaving efficiency and fabric quality.

3- Dyeing

Dyeing is the process where color meets chemistry.

It involves the interaction between dye molecules and fiber structures, allowing the dye to penetrate the inner layers of the fabric for deep, uniform, and long-lasting color results.

4- Finishing Processes

Finishing is where functionality and appearance come together.

These treatments enhance the fabric’s look, feel, and durability — making it suitable for various apparel and industrial applications. This step includes processes like softening, shrinking control, anti-pilling, and wrinkle resistance.

5- Quality Control

Before any fabric leaves our facility, it undergoes strict quality control inspections.

We test for strength, colorfastness, texture uniformity, and adherence to technical specifications — ensuring every batch meets the highest industry standards and customer expectations.

One of the leading textile manufacturer in Egypt

Dedicated Team

24/7 Hours Support

Our Exporting Network

Export-Ready Fabrics

Global Shipping

Custom Orders

International Clients

Whatever fabric you’re looking for, you’ll find it at our factory

Chiffon 150

Wool Peach